Therefore, after the device prints the PEEK model, it can be annealed directly in the device.

Through the previous knowledge popularization, we know that high-temperature cavity is a necessary condition for good molding of polymer materials such as PEEK and PEI. But why can't the cavity temperature of many large industrial-grade equipment reach 180°C+?

Equipped with a double-tooth silicon carbide extruder, it has the characteristics of large torque, super wear resistance, and no step loss. It can print all filaments below 500°C, especially carbon fiber and glass fiber materials.

Water cooling device is necessary, which is the key to smooth printing of high-temperature filament. Hot-end is an Integrated die-casting wear-resistant nozzle, which can be replaced within 30 seconds without removing other parts or screws.

For the first time, an aviation-grade heat-insulating sports protective cover is used in professional-grade equipment. Through clever design, multi-path heat dissipation, customized high-temperature resistant parts, and the use of multi-layer heat-insulating materials, when the chamber temperature reaches 180°C, the temperature of the front door, top door, screen area, body, and side panel area of the machine is within 40°C, ensuring the safety of users.

After the model is printed, there is no need to peel the model from the platform, cool it naturally, or anneal it in the annealing furnace.

You can select the "direct annealing after printing" function for the corresponding material such as PEEK, PEI, etc. on the screen in advance. You can also modify the built-in annealing temperature and time in the settings to achieve one-click annealing.

| Printing | |

| Build Volume | 250*250*300 mm |

| Filament Diameter | 1.75mm |

| Number of Nozzles | Single Extruder |

| Nozzle Diameter | 0.4mm (0.3~1.0mm optional) |

| Filament Compatibility | Engineering Plastics: PLA, ABS, ASA, PC, Nylon, PETG, PVDF,Carbon Fiber; High temperature Material: PET-CF, PET-GF, UltraPA, UltraPA-GF, UltraPA-CF, PPSU; Ultra-performance material: PEI(ULTEM™Full line), PEEK, PEEK-CF(Carbon fiber), PEEK-GF(glass fiber), PEKK, etc. |

| Speed | |

| Best Printing speed | 55 mm/s |

| Max. Printing speed | 200 mm/s |

| Electrical | |

| Input Power | 200V~240V, 20A |

| Rated Power | 2500W |

| Screen | 7'' full color touch screen, multi-language |

| Print Method | USB Connectivity/USB Disk |

| Mechanical | |

| Cooling | Air pump cooling & water cooling |

| Platform | PCB aluminum + PEEK print board |

| Positioning Precision | X Y axis 0.0127mm, Z axis 0.00125mm |

| Extruder | Directly Drive |

| Machine Construction | Fully enclosed hot chamber |

| Temperature | |

| Nozzle Max. Temperature | 480℃ |

| Chamber Temperature | 200℃ |

| Platform Max. Temperature | 200℃ |

| Software | |

| Software | Creatware, Simplify3D, Cura, Slic3r |

| Operating Systems | Windowsall, macOS |

| Print File Type | STL, OBJ, AMF, Gcode |

| Special Function | |

| Outage Restored | Save data when power is off |

| Filament Detection | Pause printing when filament run out |

| Thermal insulation | Three layer insulation+Active air cooling (Chamber temp. reaches 180 ° C, the external surface temp. is less than 40 ° C) |

| High temperature accessories | High temperature resistance motors, linear rails, belts and circuits to ensure long time high temperature printing. |

| Doors cooling | Active air cooling |

| Size & Weight | |

| Machine Size | 630*555*815mm |

| N.W | 120 kg |

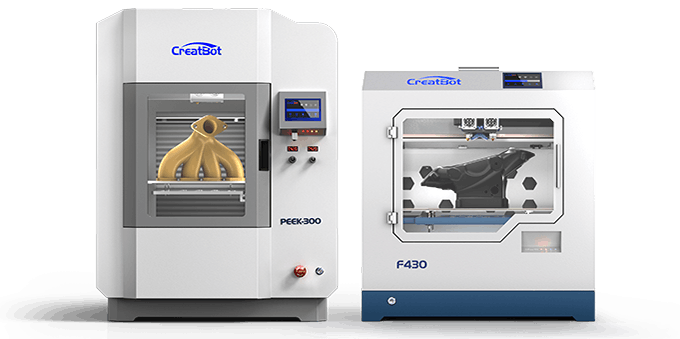

We've put together a comprehensive comparison of our 3D printers, so you can find the one that's right for your needs.