D600 Pro series has been proven to be the world's most popular professional large-size 3D printer. It has undergone 6 years of market accumulation and verification. Since its launch, we have continuously upgraded and improved the D600 Pro based on user needs and feedback. So far, we have made approximately 30 improvements in product details, incorporating new technologies, and fixing issues. Make it a very stable professional large-size 3D printer, deeply preferred by small and medium-sized enterprises.

D600 Pro 2 is a brand new product based on D600 Pro that is now being released with more advanced design concepts and deep technical reserves. D600 Pro2 HS is upgraded from the model D600 Pro2,it is a new high-speed printing version based on the in-depth development of Klipper. It adopts a new hotend with a flow rate of up to a record-breaking 90 mm³/s. The stable printing speed can reach 300mm/s, which is 5 times the speed of the D600 Pro2 model.

It has been professionally designed, has powerful performance, and features no shortcomings. Large print volume, faster speed, stronger material compatibility, simpler operating procedures, and more stable 7/24 operation. Undoubtedly, it will capture the needs of all professional 3D printer users with a size of 600mm*3 worldwide.

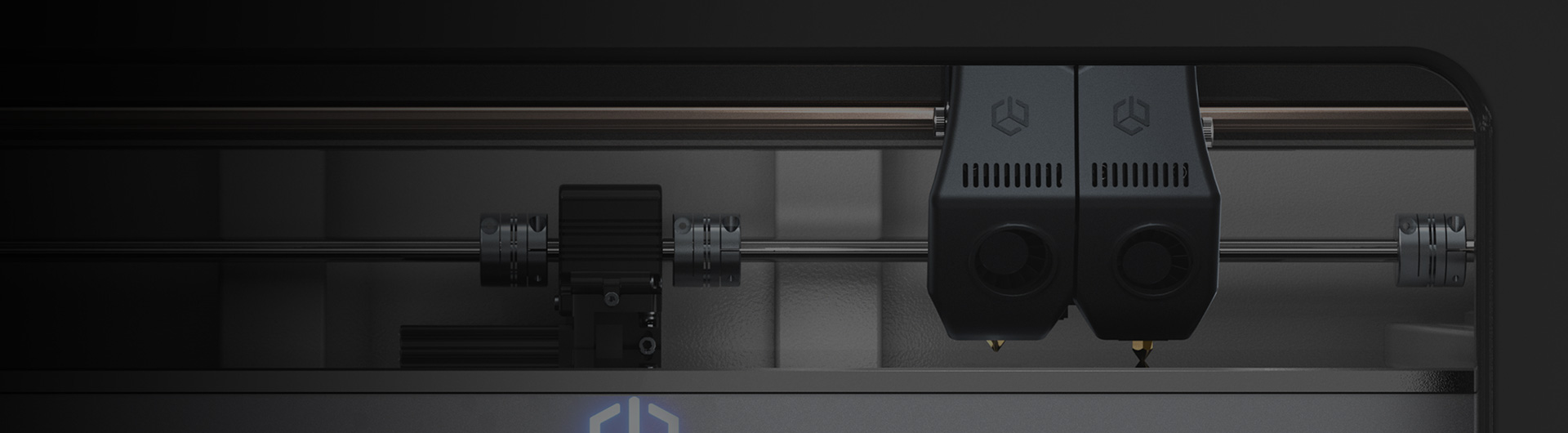

D600 Pro2 HS is embedded with new smart auto-rising dual-extruder kit with hotend temperature up to 420 ℃, it adopts a new hotend with a flow rate of up to a record-breaking 90 mm³/s. The hotend can be replaced to different size one fastly. it is able to print not only huge prototypes made of ABS, ASA with fastest speed, but also PET-CF, UltraPA-CF and more high performance material with quick remove support materials for direct application. The dual-hotend is easy to maintain and affordable to replace.

32-bit motherboard, equipped with a powerful NPU core processor, can quickly respond to any program instructions without delay.

For tall Z distance 3D printing devices, the texture of the Z-axis will deteriorate with the model height increases. Our Z-axis magic box technology can greatly reduce or even eliminate the Z-surface texture of tall models, ensuring that the surface quality of the model remains smooth and consistent.

| Printing | |

| Print Technology | FDM |

| Build Volume | Single Extrusion: 600*600*600mm Dual Extrusion: 540*600*600mm |

| Number of Nozzles | Double |

| Auto rising extruders | Yes |

| Min layer height | 0.05mm |

| Filament Diameter | 1.75mm |

| Filament Compatibility: | PLA, ABS, Carbon, Nylon, Ultra-PA, UltraPA-CF, PET-CF, PC, TPU, ASA, PETG, etc. |

| Nozzle Diameter | 0.6mm (0.3, 0.4, 0.6, 0.8,1.0mm) |

| Print File Type | GCODE |

| Temperature | |

| Max. Nozzle Temperature | 420°C |

| Max. Bed Temperature | 100°C |

| Max. Chamber Temperature | 70°C |

| Filaments Drying Temperature | 0-70°C (Timed) |

| Speed | |

| Print speed | 0-300mm/s |

| Electrical | |

| Power Requirements | 240V, 50-60Hz |

| Max. Power | 5500W |

| Screen | 7" Touch Screen |

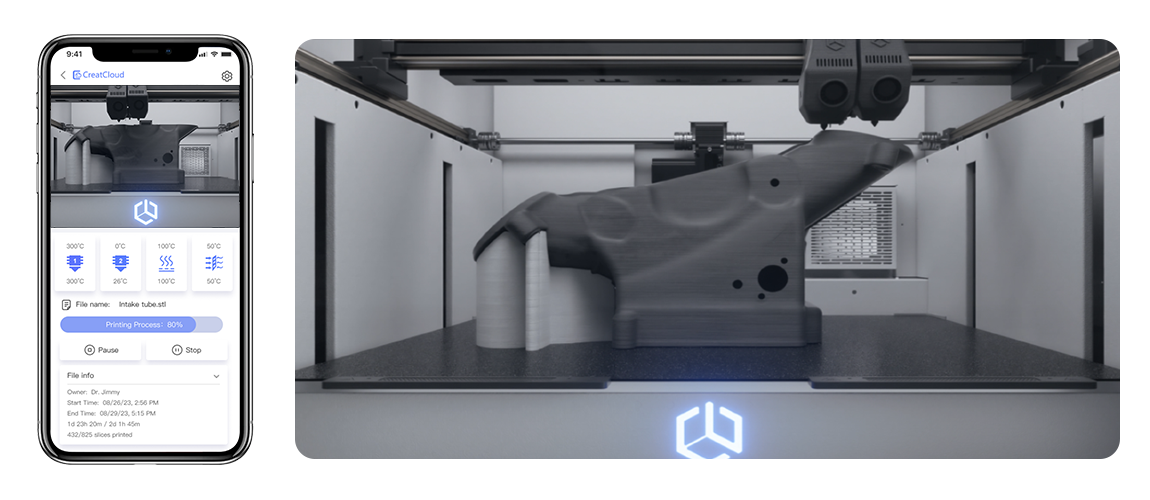

| Connectivity | USB/USB disk / WiFi |

| Software | |

| Software Bundle | CreatWare, OrcaSlicer, Cura,Slice 3r |

| Supported File Types | STL, OBJ, AMF |

| Operating Systems | Windows (7,8,10) Mac OS |

| Special Function | |

| Filament Detection | Pause printing when filament run out |

| Automatic leveling bed | Yes |

| Magic box Technolog | Perfect Z direction texture |

| Camera Control | Monitoring + Control |

| Emergency stop switch | Yes |

| Firmware | Klipper-high speed |

| Hardware | |

| X/Y motors | high-precision Servo motors |

| X/Y Axis | high-precision Linear slides |

| Air filter | HEPA+Carbon |

| Print bed | Removable magnetic platform( base on high-precision aviation aluminum plate) |

| Print surface | PEI sheet+ PEI coating |

| Mainboard | 32 bits |

| X/Y min&max | Photoelectric switch |

| Size & Weight | |

| Product Dimensions & Weight | 1080*920*1245mm 200kg |

| Packing Size & Weight | 1150*1000*1410mm 245kg |

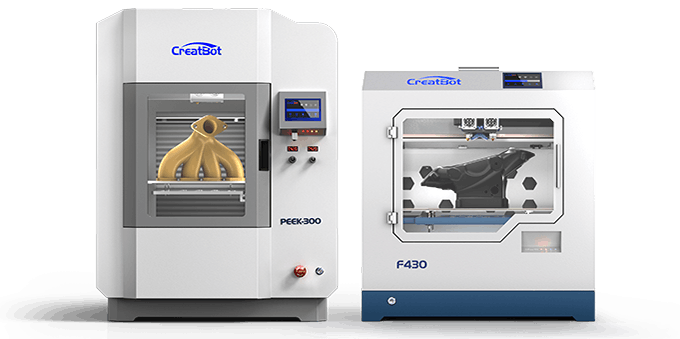

We've put together a comprehensive comparison of our 3D printers, so you can find the one that's right for your needs.